Trouble Oh trouble set me free I have seen your face

And it's too much too much for me

So, I've been having some trouble with haze in my all grain brews, thus the Cat Stevens, and I think I've tracked it down to the mash. I'm either getting some starch haze due to low mash temps or perhaps some grist due to crappy recirculation. Also, I've been getting a non-hop bitter taste in my beers that I think is from the chloramine in the water, despite 1/2 a campden tablet. Ahh, so many things to work out. Well, I'm always up for a challenge and decided to have some fun and to do a brew-off to work out some of the kinks in my brewing process. I brewed two 5 gallon batches in the same day... took 9 hours@~@. In the right corner we have the clean the clear the predictable "spring water" (SW) from a grocery store near you and in the left corner we have the cheap the tainted the hopeful "tap water" (TW) that we've prettied up with an activated carbon filter from

More Beer and a full campden tablet. I'll let them slug it out in my mouth in a month or so:) We'll see about the bitter flavor after they brew up... should go faster with the use of a starter this time... actually had to use a blow off tube!

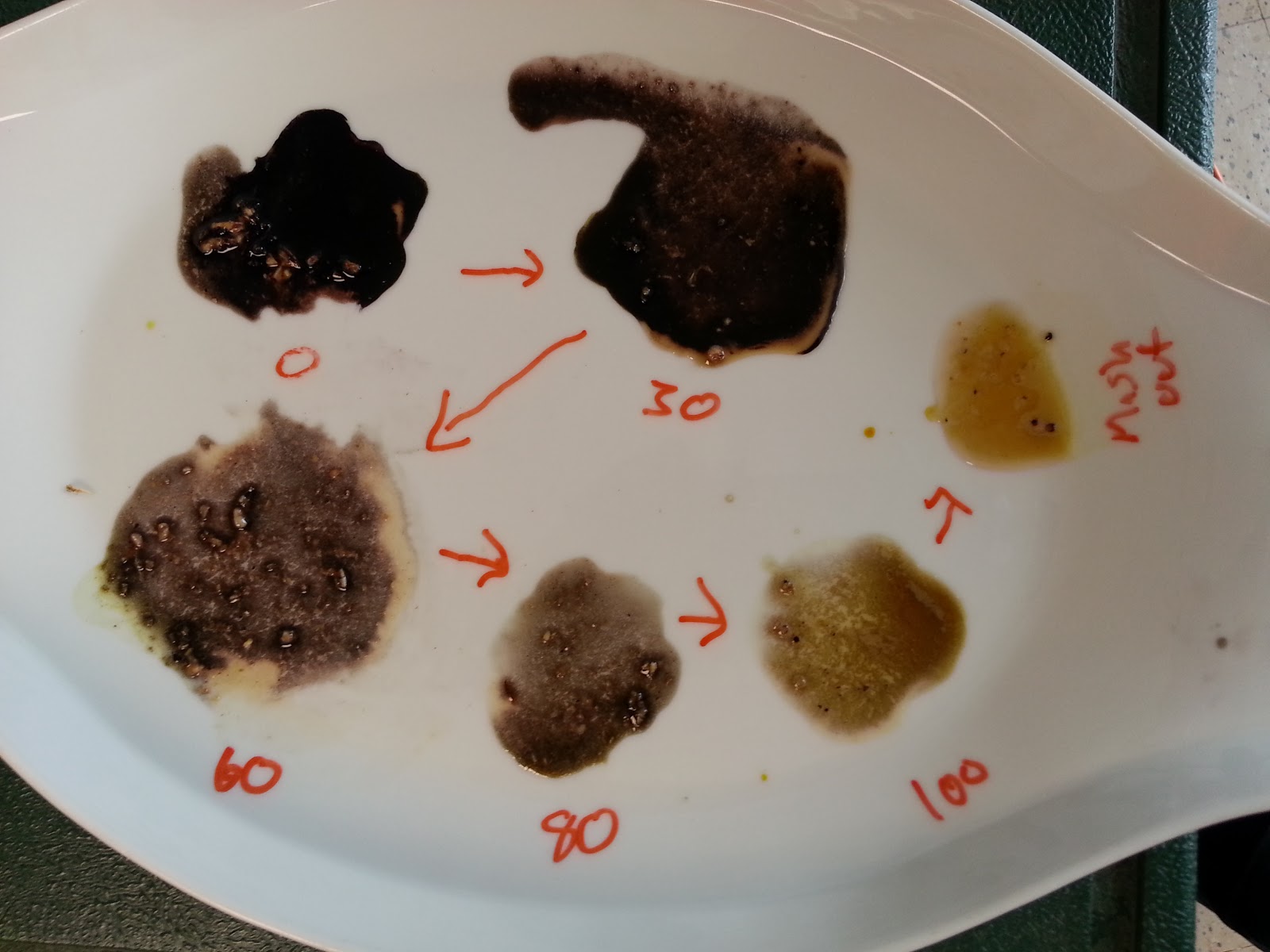

And while I'm at it, I might as well crack that haze nut: I upped the mash time to 90 min and made an effort to step up the mash temperature during the 90 min period. To make sure my mash is actually doing what it's supposed to, convert starch to maltose, I monitored starch conversion with an iodine test so I could be sure the job was done before moving on.... and it does in fact take more than 60 min in my setup. I also ditched the hop bag and added whirlfloc to the boil, hoping to get better break in my boil. In the end there was a lot more trub to deal with, but what do you know, clear freaking beer! Woo!!

Finally, I got a lot of good "advise" from the

Beer Geeking guy who seems to have gone through a lot of trial and error before attaining "good-brew" status, and he has kindly distilled those experiences in his blog, check it out.

So, back to beer. What shall I brew? Well that dear ringer IPA is damn fine if I say so myself and 4 cases sounds good to me!

Dead Ringer is an homage to a benchmark of the American IPA style that’s brewed in Michigan. American base malt and crystal malt create the big body and supporting grainy sweetness, while charge after charge of 100% Centennial hops deliver pronounced bitterness with a dominant citrus aroma and flavor. In the glass you get a pale amber color, hop intensity and malt density - substance with the soul of a session beer.

O.G: 1.064 READY: 6–8 WEEKS

Suggested fermentation schedule:

- 1–2 week primary; 2–4 weeks secondary;

2 weeks bottle conditioning

STARTER CULTURE

1300ml bottled water, 1 cup light DME, boil 10 min, cool with ice bath in pot, add to 2L flask, pitch 100ml rehydrated US-05 yeast, and incubate on stir plate for 17-20hrs. Used this stir plate kit:

Stir Starter

MASH INGREDIENTS

- 11 lbs. Rahr 2-Row

- 1 lbs. Briess Caramel 40

MASH SCHEDULE: SINGLE INFUSION

Sacch’ Rest: 152° F for 60 minutes

Mashout: 170° F for 10 minutes

Spring water mash: 16q of 170F water to a mash temp of 152F. After 40 min temp dropped to 150, 60 min down to 146.5. Added 2q boiling water to 150F. At 70 min 2q boiling water added to 154.5. At 80 min 2q boiling water to 158F. Forgot gypsum so added 1tsp and 2tsp pH 5.2 mix; pH went from 5.6 to 5.2. At 90 min added 5q boiling water for mashout at 163F for 10 min. Recirculate: flush 2 qal quickly to pull off grist from bottom, then slowed to 1q/min for 10min. The out flow was very clear! Sparge water at 170F, 5gal (2tsp 5.2 added). My boils have reduced the wort a bit low so I added 7.25 gal to the pot. Heat to boil 15min. OG 1.055 but expected because of the extra wort in the brew pot (boiled down to 6 gal).

Tap water mash: tap water was run through activated carbon filter and treated with 1 campden tablet the night before. Strike water heated to 175F, 14q added to 153F. After 10 min added 1tsp gypsum and 2tsp of pH 5.2 (another 2 tsp to sparge water). At 30 min 149F. At 45min 3q boiling water to 154.5F. At 60 mi added 2q boiling water to 158F. At 90 min added 3q of boiling water to 163F for 10 min. Recirculate: flush 2 qal quickly to pull off grist from bottom, then slowed to 1q/min for 10min. Clear out flow! Sparge water at 170F, 5gal. My boils have reduced the wort a bit low so I added 7.25 gal to the pot (boiled down to 6 gal). Heat to boil 15 min. No OG because I dropped my hydrometer!!!

BOIL ADDITIONS & TIMES

0.75 oz. Centennial (60 min).... actually added 1oz

1 oz. Centennial (20 min)

1 whirlfloc tab (10 min)

2 oz. Centennial (5 min)

SW boil cooled in 35min to 72F while TW boil cooled in 50min. About 1 inch of trub in each carboy.

DRY HOPS

1 oz. Centennial – add to secondary fermenter

one to two weeks before bottling day

YEAST

DRY YEAST (DEFAULT): Safale US-05.

Optimum temperature: 59–75°F

Pitched 600ml starter to SW wort at 72F, and 600ml to TW wort at 70F.

FERMENTATION:

Pitched 600ml of a starter culture into SW brew at 72F and the TW brew at 70F (2.5 hours later). SW showed activity 4 hours later while the TW brew took a bit longer ~8 hours. Both were fermenting strong with a hefty head of krausen the next day and were holding at around 70F (see video below). I had to put a blowoff tube in the TW batch on day two because it clogged the airlock. The fermentation continued between 66 and 70F for 4 or 5 days then slowed and the krausen fell at 6(SW)-7(TW) days. Racked to a secondary on the 8th day. I used a CO2 bike tube inflator to flush CO2 into the secondary before racking. A quick taste of each and the SW seems a bit more crisp than the TW, but both taste good, nice and bitter needing those dry hops! After 3 days in the secondary the TW batch looks more clear than the SW batch. I added 1oz of centennial hops after a week in the secondary, then bottled 6 days later. The temp ranged between 64-66F. The FG on both beers was 1.01, so around 6% alcohol with the OG of 1.055.

BOTTLING

At bottling (4oz corn sugar) both beers tasted good! The SW is a bit smoother on the mouth and the TW has a more crisp feel, which I prefer in an IPA. Both brews were also very clear, so I think my "flush out" before the laughtering helped a lot, that and the extra 30 min in the mash. I let the bottles carbonate for 3 weeks then chilled to 32F. A cold haze formed and dropped out after two weeks.

CONCLUSION

Both beers are a bit on the bitter side (maybe shouldn't have added the extra 0.25oz of hops at 60min) and I just feel like they need more hop flavor... maybe a few more ounces in the dry hop. Head retention is good on both. As for off flavors, I perceive a bit of solventy notes in both... maybe some fusel alcohols from the high ferm temps.. will try to keep them down at 66-68F, at least for the first few days. Besides that there are distinct differences in flavor. The SW is smoother feeling, but almost too soft, especially for an IPA. The TW is more crisp with a drier finish. At this point, both my wife and I like prefer the tap water version. Update, after 2 months in the fridge the beers have matured nicely, and the TW has a more apparent estery profile, one that is less prominent in the SW. Due to that the SW takes the lead in flavor, but both beers taste good and since the esters are likely due to the fermentation temp, I'd say that both the tap water (carbon filtered and campden tab) and spring water work just fine. It's a draw.

The brew

Iodine test of Spring Water mash

OG 1.055: A little low. Clear wort!

Pitched that yeast!

Tap water mash iodine test.

Tap water brew.

Pitched yeast... broke my hydrometer!!

16 hours after pitching

Day two and had to go blowoff on the TW.

TW Day 2: krausen!

Dry hops

4 cases of brew!